Engineering Plastics Sales

“YUJIN Ltd” delivers plastics produced by

Sabic Innovative Plastics

(USA).

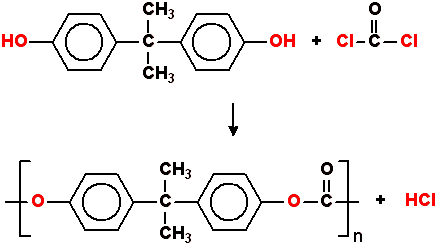

Sabic IP arranges complete technological cycle of polycarbonate (PC) (from synthesis of polymeric base to production of granules) polybutylenterephthalate (PBT), polyphenylenoxide (PPO), polyetherimide (PEI), thermoplastic polyimide (TPI).

Sabic IP is successor of “General Electric Plastics” (USA).

Olga Chkhetiani

Engineering Plastics Sales Manager

GSM: +38 050 170 25 59E-mail: chkhetiani@yujin.com.ua

SABIC IP plants, satisfying requirements of Europe, Africa, the Middle East, are located in Bergen on Zoom (the Netherlands) and Cartagena (Spain).

SABIC IP plants, satisfying requirements of Europe, Africa, the Middle East, are located in Bergen on Zoom (the Netherlands) and Cartagena (Spain).

SABIC IP (along with BAYER AG) was the first in the world which started the production of polycarbonate (opening in 1953, start of serial production in 1958).

SABIC IP (along with BAYER AG) was the first in the world which started the production of polycarbonate (opening in 1953, start of serial production in 1958).

- Lexan

-

Polycarbonate(PC)

- Valox

-

Polybutyleneterephthalate(PBT)

- Noryl

-

Polyphenylenoxide(PPO)

- Cycolac

-

Acrylonitril-butadienstyrol(ABS)

- Ultem

-

Polyetherimide(PEI)

- Ultem Foam

-

Polyethirimid foamed(PEI)

- Geloy

-

Akrylonytrile-styrolacrylate(ASA)

- Extem

-

Thermoplastic polyamide(TPI)

Basic products are divided into groups depending on polymeric base. Definite trade name corresponds with each group.

Depending on their properties, plastics of different brands are available inside each group.:

- indices of melting flowability

- contents of a filler (fiber glass, as a rule)

- degree of flammability (fire-resistance)

- presence of antioxidants (protection from UV-radiation)

- availability of permit for contact with food products (FDA-certificate)

- presence of additives, simplifying the withdrawal of a part from a press mold

- availability of polymer base modifications

Detailed information about the products and data sheets are available at Sabic IP official site .

- Cycoloy

-

PC + ABS

- Xenoy

-

PC + PBT

- Xylex

-

PC + PET

- Noryl GTX

-

PPO + PA

- Noryl PPX

-

PPO + PP

- Colorcomp

-

Plastics with high contents of pigment

- Faradex

-

Plastics reflecting electro-magnetic radiation, current conducting

- Konduit

-

Plastics with higher thermal conductivity

- Lubricomp, Lubriloy

-

Plastics with low friction coefficient

- Stat-Kon,

Stat-Loy -

Current conducting plastics

- Thermocomp, Thermotuf

-

Plastics with higher rigidity

- Verton

-

Plastics with higher strength (filler-increased length fiberglass)

LNP Products are plastics which have special properties.

As distinct from base products, LNP-products are grouped depending on typical and distinctive properties.

Each group can have plastics with different polymer base.

Detailed information about the products and data sheets are available at Sabic IP official site .

Natural condition plastics (that is without pigments) can be transparent and non-transparent. Transparent plastics:

- Lexan (PC)

pure - Ultem (PEI)

amber - Extem (TPI)

amber - Xylex (PC+PET)

pure

Other plastics are transparent and are naturally white with different shades.

Sabic IP produces natural and pigmented plastics. If plastics are naturally white after coloring they can be:

- transparent (but passing certain wave-length light)

- semi-transparent (smoky)

- non-transparent

Each color is given Sabic Ip inner code. Inside each grade name there is a coding. Customers can choose any color from those available or give an individual order for the combination of a new color.

All information about colors is held here.

- Aircraft industry

- Motor industry

- Electrical engineering and electronic industry

- Medical equipment

- Sanitary equipment and ventilation

- Packing equipment

- Electric lighting

- Production of fibers and textile

- Construction industry

- Transport machine-building industry

Example of plastics designation for the entry in production forms and records and to order:

143R – grade

111 – color code.

815UX – grade

WH7D194 – color code