Engineering

About 85000 kinds of plastics in the world are manufactured by different producers. Choice of plastics considerably influences their quality, operational performance and cost of a product.

The process of plastics choice consists of the following stages:

-

1.Formulation of CTQ.

-

2.Choice of specific material (materials) which correspond to CTQ adjusted to minimal cost.

-

3.Production of pilot batch and verification of material (tests of parts in laboratory conditions).

-

4.Validation of material (actual-service test).

Our company realizes support in all four stages of material choice.

Service in question is free and refers only to plastics Sabic IP.

Molding process determines specific requirements to geometric shape of parts.

Non-observance of these requirements can lead to decreased mechanical durability, surface defects, decrease of process regulation, increase of production cost.

Our company carries out expert examination of design plans to estimate its conformity with molding technological requirements and requirements of plastics producer.

Service in question is free and refers only to plastics Sabic IP.

Molding process determines specific requirements to geometric shape of parts.

Non-observance of these requirements can lead to decreased mechanical durability, surface defects, decrease of process regulation, increase of production cost.

Our company develops design plans and specifications to the requirements of customers, plastic producers and molding technological requirements.

Service in question is free and refers only to plastics Sabic IP.

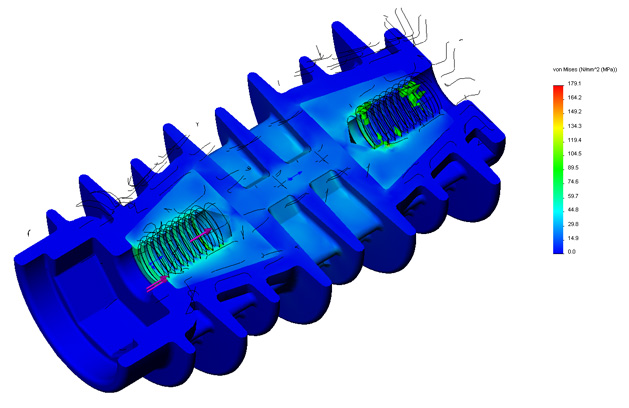

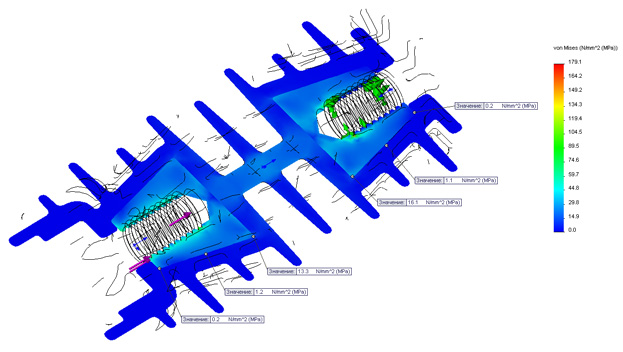

Key factor, determining parts serviceability and durability, is its resistance to mechanical load.

Inner strain and deformation of all volume of parts, as a result of external mechanical load, are determined within the process of stress analysis.

Knowledge of stress and deformation helps to optimize the construction, choose the right material, avoid the destruction of parts in the process of exploitation.

Our company makes stress-analysis of parts based on input data provided by the customer.

Service in question is free and refers only to plastics Sabic IP.

Cold-channel runner system of the mold must be balanced and have certain geometric dimensions.

Non-observance of these requirements can lead to decreased mechanical durability, surface defects, decrease of process regulation, increase of production cost.

Our company carries out expert examination of cold-channel runner systems to estimate its conformity with technological requirements of injection molding and demands of plastics producer.

Service in question is free and refers only to plastics Sabic IP.

The process of parts formation by molding is characterized by such technological parameters

- Injection velocity (pressure)

- Time of endurance under pressure

- Value of back pressure

- Injection dose

- Temperature in zones of cylinder heating

- Nozzle temperature

- Press mold temperature

- Time of cooling

- Etc.

It is necessary for each press mold and each injection molding machine to select certain combination of technological parameters which guarantees the necessary quality of the product and decrease of production expenses by reducing cycle time.

Our company gives support in selection of technological regime of molding based on our experience, experience of our partners and recommendations of plastics producers.

Service in question is free and refers only to plastics Sabic IP.

Molding is realized on special equipment—injection molding machine (IMM).

Parts formation is done by injecting melted material into molds.

Separate mold is necessary for each type as well as IMM which is technically usable for the production of parts.

Accurate choice of equipment guarantees the necessary quality of parts and minimum production cost.

Our company gives support in the choice of IMM and other technological equipment necessary for molding.

Input Data For Choosing IMM:

- Weight or volume of part (including runners).

- Type of material.

- Drawing, sketch or sample of articles.

- Number of cavities.

- Sketch of lay-out (arrangement) of cavities relative to the plane of mold opening (or sample of molding together with runners).

- Mold dimensions (in open and closed state).

Service in question is free and refers only to plastics Sabic IP.